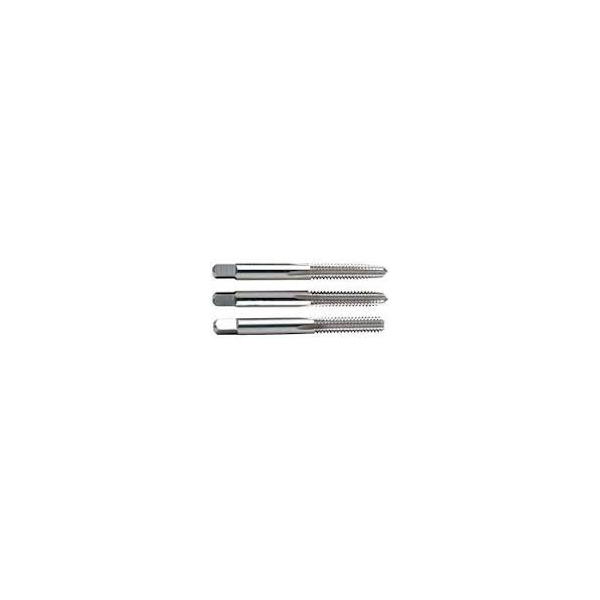

Hand taps

HSS-G screw taps are suitable for machinable raw materials up to 900 N/mm². The design in HSS-E for hard to machine raw materials up to 1200 N/mm² and vapourised hand screw taps are particularly suited to wear-resistant steels up to 1400 N/mm².

The taps can be distinguished from their thread leads and marking. Pre-cutters (rougher) are marked on their shank with one and middle cutter (intermediate) with two rings. The finished cutter does not carry a ring and is generally not marked.

- Rougher = 6-8 Thread pitch

- Intermediate = 4-5 Thread pitch

- Finisher = 2-3 Thread pitch

It is recommended that the finishing cutter should only be used for trimming damaged threads. The rougher, intermediate and finisher can be ordered separately.

!!WE ALSO DO ALL THESE TYPES FOR FURTHER INFORMATION CONTACT SALES!!

Hand taps M (metric) , (metric) left hand Mf (metric fine) f (metric fine) left hand BSW (Whitworth) BSW (Whitworth) left hand

- BSF (brit. standard fine) BA (brit. assn. thread) UNC (Unified Coarse) UNC (Unified Coarse) left hand UNF (Unified fine)

- UNF (Unified fine) left hand UNEF (Unified extra fine) G (BSP) Pipe-thread PG (Armoured tube thread)

- Tr (trapezoidal thread) American UNx8 thread Whitworth screw thread for gas cylinders